Cangzhou, Hebei, China

Response Time: < 24h

Response Rate: 0%

| Model No.: Cold Bending Form... | Brand: MT | Place of Origin: China |

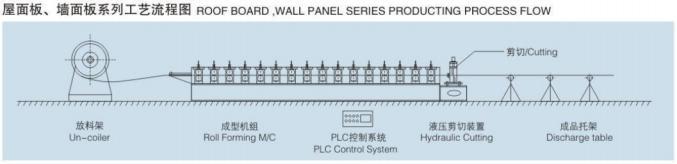

1- 1 Processes and components

uncoiler— Roll forming machine— computer control system— hydraulic

control system forming cutter receiving table

2. Main Specification and components:

2-1. Main Specification:

|

No. |

Main parameter of roll forming machine |

|

|

1 |

suitable material |

PPGI/GI |

|

2 |

Roller |

45# steel through striking, commom lathe coarse machining, CNC lathe finish machining, polishing, plating hard chrome on surface. |

|

3 |

Motor power Pump station power |

5.5kw 380V 50HZ 4Kw 380V 50HZ |

|

4 |

Thickness of raw material |

0.3-0.8mm |

|

5 |

Productivity |

3- 16m/min

|

|

6 |

diameter of shaft |

¢ 75mm.MATERIAL IS 45# STEEL. |

|

7 |

Voltage |

380V 50Hz 3phases |

|

8 |

Mid-plate thickness |

16mm |

|

9 |

Structure of machine |

350mm "H" steel welding |

|

10 |

Forming Stations |

11 rows 9rows |

|

11 |

Chain |

1 inch |

|

12 |

Automatic control system |

Delta PLC |

|

13 |

Reducer |

4# Planetary Cycloidal reducer,speed ration1:59 |

2-2 . Specification of components

|

|

No |

|

Technical Specification |

|||

|

|

1 |

Manual uncoiler 2 SETS |

Hold the coil sheet Coil inner diameter:508±30mm Max coil width:1200mm Carrying capacity:5000kg |

|||

|

|

|

|

|

|||

|

2 |

Feeding platform |

Function and feature: put the raw material (steel plate) on the plat to manufacture and process, it can guarantee that the products are neat, parallel and everything is uniformity. |

|

|||

|

3 |

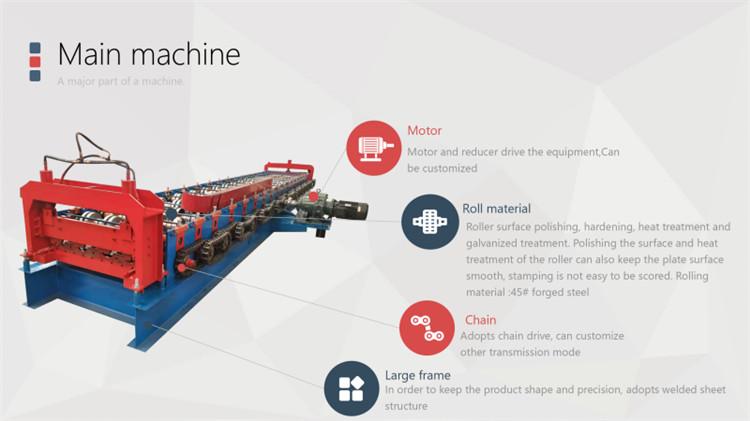

Main machine |

In order to keep the product shape and precision, adopts welded sheet structure, motor reducer drive, chain transmission, roller surfaces polishing, hard planting, heat treatment and galvanization treatment. The polished surface and the heat treatment towards the roller also can keep the plate surface smooth and not easy to be marked when it is being stamped. Rolling galvanization thickness:0.05 mm Rolling material: Forging Steel 45# |

|

|||

|

4 |

Shearing mechanism |

It adopts the hydraulic drive and automatic location to decide the dimension and cut the target products. It contains one set of cutting tools, one hydraulic tank Material of the cutting blade :Cr12 |

|

|||

|

5 |

Hydraulic system

|

It is controlled by gear wheel oil pump. After filling the hydraulic oil into the hydraulic oil tank, the pumps drive the cutter machine to begin the cutting job. The system includes a set of hydraulic tank, a set of hydraulic oil pump,2 hydraulic pipes. And 1 sets of electromagnetism valves. Hydraulic oil :40#

|

|

|||

|

6 |

Computer control cabinet |

It adopts industrial computer to control. The target piece’s length is adjustable and digit of it can be adjusted. Computed mode has two modes: automatic and manual one. The system is easy to operate and use. Processing precision : ±2.00mm It contains:Touch screen, programmer, transformer for the electronic machines and kits of every part. Delta PLC with frequency converter The seller should provide Chinese and English language screen.

|

|

|||

|

7 |

Counter |

One counter gauges length, pulses, and decides length

|

|

|||

|

8. |

Runout table |

|

|

|||

|

9

|

Payment terms and delivery |

Payment:30%TT in advance,balance should be paid by TT after inspection confirmation before shipment./According to customer requirements Delivery time:30-40 Working days |

|

|||

|

10 |

Warranty |

One year.We will support the technical support whole life |

|

|||

|

9 |

Payment terms and delivery |

Payment:30%TT in advance,balance should be paid by TT after inspection confirmation before shipment./According to customer requirements Delivery time:30-40 Working days |

|

10. |

Warranty |

One year.we will support the technical support whole life |

The important parts of the machine are rubbed with anti-rust oil. PLC and other parts are wrapped with foam to prevent moisture. Then by professional technical personnel into the container.